Shipping containers are essential to modern logistics, designed to transport goods across the globe efficiently and securely. Understanding the technical aspects of a shipping container’s anatomy is crucial for professionals in the transportation and logistics industries. This article provides a detailed examination of the structural components, materials, and specialized features that make up a standard shipping container.

1. Basic Structure of the Container

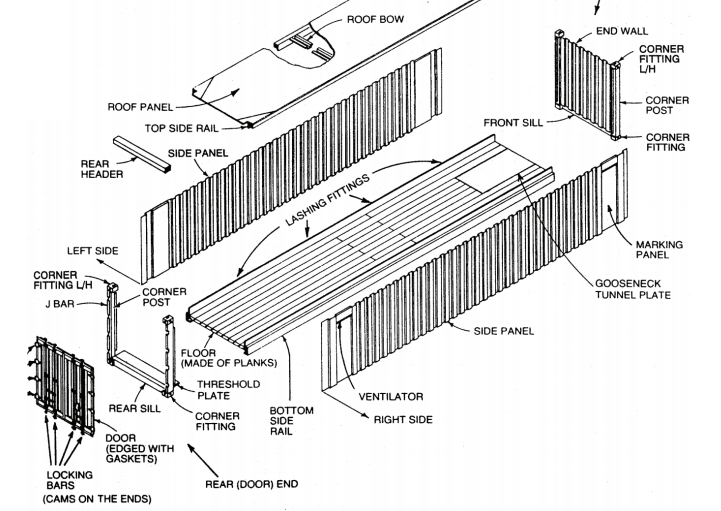

Corner Posts: The corner posts are the vertical beams located at each corner of the container. Made from high-strength steel, these posts are the primary load-bearing elements, supporting the entire structure during stacking and lifting operations. The corner posts are engineered to endure extreme stresses, ensuring the container’s stability when stacked up to eight units high in a typical container ship.

Corner Castings: Corner castings are solid steel blocks welded to the top and bottom of each corner post. These castings feature apertures designed to accommodate twist-lock mechanisms used in lifting and securing containers. Their precise dimensions are standardized globally, allowing seamless intermodal transportation across different transport modes, including ships, trains, and trucks.

Side and End Walls: The side and end walls are typically constructed from corrugated steel sheets, which are both lightweight and robust. The corrugation enhances the walls’ ability to withstand impact and pressure, distributing load stress evenly across the container’s surface. The end walls are reinforced, particularly around the door frame, to ensure durability and security during repeated loading and unloading operations.

Roof Panel: The roof panel of a shipping container is usually made from corrugated steel or aluminum. The corrugation in the roof provides additional strength, helping the container resist deformation under the weight of other containers stacked on top. The roof is designed to be watertight, protecting the contents from rain and other environmental factors.

Flooring: The flooring in a shipping container is typically composed of marine-grade plywood or bamboo, supported by steel cross members underneath. The plywood is treated to resist moisture and fungal decay, ensuring long-term durability even in humid conditions. The floor must be capable of supporting heavy machinery or dense cargo without warping or breaking, making material selection and construction critical.

2. Container Components

Doors: Shipping container doors are located on one end of the container and are built to be both secure and accessible. Each door consists of a steel panel with an internal rubber gasket that seals the container when closed, making it watertight. The doors are reinforced with vertical and horizontal stiffeners to prevent warping under stress. They are equipped with four locking rods, which engage with cam keepers on the frame to ensure a tight seal. The handles of these locking rods are designed to be padlocked, adding an additional layer of security.

Locking Mechanism: The locking mechanism on a shipping container is vital for maintaining security during transit. It consists of locking rods, cam keepers, and locking handles. The rods run vertically along the door, engaging with the cam keepers attached to the door frame. When the handles are rotated, the rods are drawn into place, securing the door. This mechanism is designed to be robust, resisting tampering and environmental wear.

Ventilation: Ventilation openings are strategically placed in the upper portions of the container’s side walls. These vents are small enough to prevent water ingress while allowing air circulation, reducing the risk of condensation and moisture buildup inside the container. Proper ventilation is crucial for transporting goods that are sensitive to humidity, such as electronics, textiles, and food products.

Forklift Pockets: Forklift pockets are reinforced slots located at the bottom of the container, allowing it to be lifted and moved by a forklift. These pockets are particularly common in smaller containers or specialized units designed for easy handling in warehouses and storage facilities. The pockets are designed to accommodate the forks of standard forklifts, with enough reinforcement to prevent damage during lifting.

3. Material Analysis

Corten Steel: Most shipping containers are constructed from corten steel, also known as weathering steel. This material is specifically chosen for its exceptional resistance to corrosion, which is critical in the harsh marine environments where containers are often used. Corten steel forms a stable rust-like appearance after exposure to weather, which acts as a protective layer, preventing further corrosion and extending the container’s lifespan.

Aluminum: Aluminum is used in some specialized containers, particularly those designed for air freight or industries where weight is a significant concern. Aluminum containers are lighter than their steel counterparts, reducing transportation costs and increasing fuel efficiency. However, aluminum is not as strong as steel, so these containers are typically used for lighter or less dense cargo.

Plywood: The flooring of a shipping container is usually made from marine-grade plywood, which is known for its high durability and resistance to moisture. The plywood is often treated with preservatives to enhance its resistance to decay, especially in the wet and humid environments typical of marine transport. In some cases, bamboo plywood is used as a sustainable alternative, offering similar strength and durability.

4. Container Types and Configurations

Standard Dry Containers: The most common type of shipping container is the standard dry container, used for transporting general cargo. These containers are fully enclosed, protecting the contents from the elements. They are available in various sizes, with 20-foot and 40-foot lengths being the most prevalent. The interior of these containers is designed to maximize usable space, with minimal intrusion from structural elements.

Refrigerated Containers (Reefers): Refrigerated containers, or reefers, are equipped with built-in refrigeration units to transport perishable goods. These containers are heavily insulated to maintain a consistent internal temperature, regardless of external conditions. The refrigeration units are powered by external generators or by the container ship’s power supply, ensuring that the cargo remains at the required temperature throughout the journey.

Open-Top Containers: Open-top containers are designed for cargo that is too large or awkward to fit through standard container doors. These containers have a removable tarpaulin roof, allowing cargo to be loaded from above. The sides of the container are reinforced to compensate for the lack of a fixed roof, ensuring that the structure remains stable during transport.

Flat Rack Containers: Flat rack containers are used for transporting oversized or heavy cargo that cannot be accommodated in standard containers. They have collapsible sides, which can be folded down to create a flat, open platform. This design is ideal for machinery, vehicles, or large industrial equipment. Flat rack containers are built to handle heavy loads, with reinforced frames and floors to support the weight.

High Cube Containers: High cube containers are similar to standard dry containers but with an additional foot of height, providing extra space for voluminous cargo. These containers are particularly useful for transporting goods that require more headroom, such as large appliances or stacked pallets. The increased height allows for more efficient use of space, reducing the number of containers needed for transport.

5. Specialized Features

Lashing Rings: Lashing rings are installed along the interior walls and floor of the container, providing anchor points for securing cargo. These rings are essential for preventing cargo from shifting during transit, which could cause damage or imbalance the container. The lashing rings are typically made from high-strength steel and are capable of withstanding significant forces, ensuring that the cargo remains securely in place.

Insulation and Lining: Some containers are equipped with specialized insulation and lining to meet the needs of specific cargo types. Thermal insulation is commonly used in refrigerated containers to maintain temperature, while acoustic insulation may be used for transporting sensitive equipment. The lining materials vary depending on the cargo, with options including foam, rubber, and specialized coatings designed to protect the interior surfaces.

Container Coatings: The exterior of a shipping container is coated with protective paint to prevent rust and corrosion, especially in harsh marine environments. These coatings are typically applied in multiple layers, including a primer, an anti-corrosion layer, and a topcoat that provides additional resistance to UV light and saltwater. The interior may also be coated with specialized materials to protect against chemical exposure or to meet food-grade standards for transporting consumables.

Conclusion

The anatomy of a shipping container is a complex combination of engineering and material science, designed to create a versatile and durable structure capable of withstanding the rigors of global transportation. By understanding the technical details of each component, from the corner posts to the lashing rings, logistics professionals can better appreciate the container’s role in ensuring the safe and efficient movement of goods worldwide.