Introduction

Forged steel is a crucial material, renowned for its strength, durability, and reliability. It is widely used in industries like container manufacturing, ensuring safe and efficient logistics.

What is Forged Steel?

Forged steel is created by heating steel to a malleable state and shaping it under high pressure. This process refines the grain structure, enhancing its mechanical properties compared to other steel types.

Advantages of Forged Steel

- Strength & Durability: Exceptional resistance to impact and stress.

- Wear & Fatigue Resistance: Reduced porosity and refined grain structure.

- Enhanced Properties: Improved ductility, toughness, and tensile strength.

Types of Forged Steel

- Hot Forged Steel: Shaped at 950°C – 1250°C, offering excellent formability.

- Hardened Steel Forging: Balanced strength and ductility at 750°C – 950°C.

- Cold Forged Steel: Superior surface finish, shaped at up to 150°C.

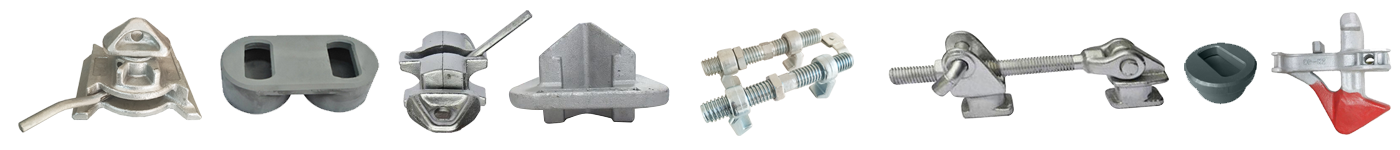

Applications in Container Parts

Forged steel is essential in the manufacturing of container components:

- Corner Castings: Ensure stability and strength.

- Twist Locks: Secure containers during transit.

- Lashing Rings: High load-bearing capacity.

- Locking Bars & Handles: Provide robust security.

- Hinges: Durable for frequent use.

- D-Rings & Tie-Down Cleats: Reliable for cargo securing.

Conclusion

Forged steel is indispensable in container logistics, offering unmatched strength and reliability. By using forged steel parts, businesses can ensure the safety and efficiency of their operations, protecting both containers and cargo.